Rīpene Koiri Parahi CuSn4 CuSn6 CuSn8 Phosphor Tin C5191

Taipitopito mō te CuSn4 CuSn6 CuSn8 Phosphor Tin Bronze Coil Strip C5191:

Rīpene Koiri Parahi CuSn4 CuSn6 CuSn8 Phosphor

Ko te CuSn6 - UNS.C51900 Phosphor Bronze Alloys, he parahi tine 6% e tohuhia ana e te huinga tino pai o te kaha me te kawe hiko. Ka whakamahia mō te hononga me ngā puna kawe-auau i roto i ngā hononga. I roto i te parahi tine 4-8% C51900 he kawe hiko teitei, ko te kaha teitei rawa atu ka taea te tae atu he nui ake i te C51100 me te C51000. Mā te whakapūmau anō i muri i te tukanga hanga matao ka taea te whakapai ake i te āheinga piko.

Te hanganga matū o te Phosphor Bronze C51900

| Ngā tuhinga | Te hanganga matū | |||||

| GB | UNS | EN | JIS | Cu% | Sn% | P% |

| QSn6.5-0.1 | C51900 | CuSn6 | C5191 | Rem | 5.5-7.0 | 0.03-0.35 |

| Te Hanganga Matū | |||

| % | |||

| Sn | P | Cu | poke |

| 7.0~9.0 | 0.15~0.35 | Para. | ≤0.1 |

Ngā āhuatanga hangarau o te parahi Phosphor

| Ngā Āhuatanga Mīhini | |||||

| Te riri | TS(N/mm²) | Te roanga (%) | Te pakeketanga (Hv) | ||

| M | O | O60 | ≥345 | ≥40 | / |

| Y4 | 1/4H | H01 | 390-510 | ≥35 | 100-160 |

| Y2 | 1/2H | H02 | 490-610 | ≥8 | 150-200 |

| Y | H | H04 | 590-705 | ≥5 | 190-230 |

| T | EH | H06 | 585-740 | / | 200-240 |

| TY | SH | H08 | ≥735 | / | ≥230 |

| Ngā āhuatanga miihini | |||||||

| Kāwanatanga | Te pakeketanga (HV) | Whakamātautau kume | Whakamātautau piko | ||||

| matotoru mm | kaha kume MPa | % whakaroa | matotoru | ngā koki | ID | ||

| 0 | - | 0.1-5.0 | ≥315 | ≥42 | ≤1.6 | 180° | 50% o te matotoru |

| 1/4H | 100-160 | 0.1-5.0 | 390-510 | ≥35 | ≤1.6 | 180° | 100% o te matotoru |

| 1/2H | 150-205 | 0.1-5.0 | 490-610 | ≥20 | ≤1.6 | 180° | 150% o te matotoru |

| H | 180-230 | 0.1-5.0 | 590-685 | ≥8 | ≤1.6 | 180° | 200% o te matotoru |

| EH | 200-240 | 0.1-0.2 | 635-720 | - | - | - | - |

| >0.2-5 | ≥5 | - | - | - | |||

| SH | ≥210 | 0.1-5.0 | ≥690 | - | - | - | - |

Ngā Āhuatanga o te Parahi Phosphor C51900 mō ngā Rīpene Parahi Phosphor

- Te tere whakaroa ≥25%

- Te tauwehenga o te ngāwari: 125GPa

- Kaha tuku: ≥90% kaha kume

- Mahi ngenge

- Mahi whakakikorua

- He mahi whakarewa tino pai

- He tino pai te mahi matao, ngā āhuatanga kukume hōhonu, ngā āhuatanga piko

Te Parahi Phosphor C51900 Te whakamahinga noa

E whakamahia whānuitia ana te parahi phosphor i roto i te mokamoka CPU rorohiko, te taunga waka, ngā pātene waea pūkoro, ngā hononga hiko me ētahi atu mara hiko hangarau teitei.

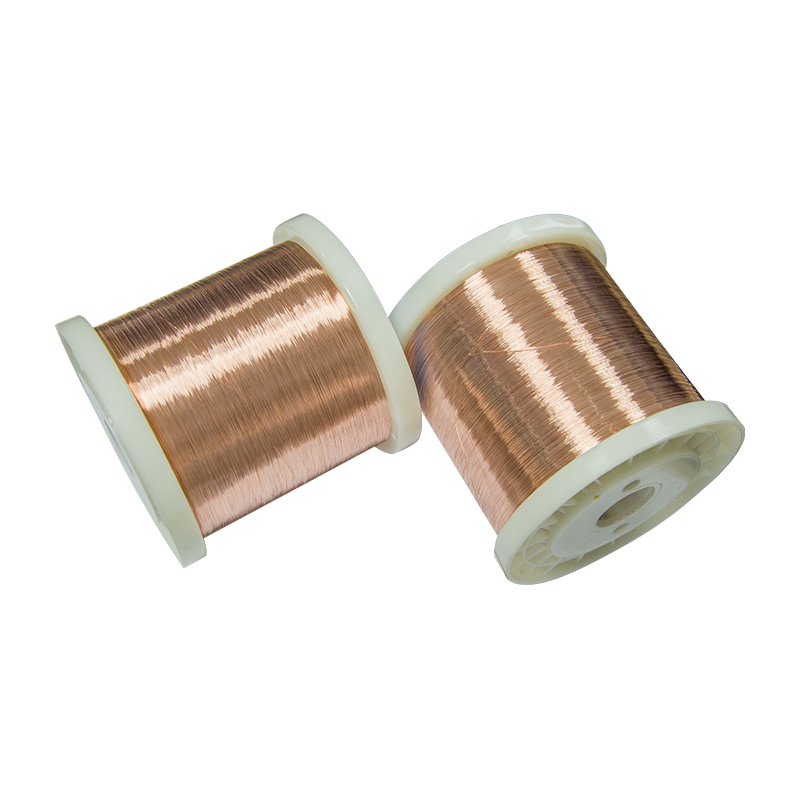

Ngā pikitia taipitopito hua:

Aratohu Hua e Pā Ana:

Ko tā mātou whāinga he "hoa ki te kiritaki, he aro ki te kounga, he whakauru, he auaha". Ko te "pono me te ngākau pono" te mea pai rawa atu mō tā mātou whakahaere mō te CuSn4 CuSn6 CuSn8 Phosphor Tin Bronze Coil Strip C5191, ka tukuna te hua ki te ao katoa, pērā i: Colombia, Rwanda, Angola. Ka taea e mātou te whakatutuki i ngā hiahia o ngā kiritaki i te kāinga me tāwāhi. E mihi ana mātou ki ngā kiritaki hou me ngā kiritaki tawhito ki te haere mai ki te kōrero me te whiriwhiri tahi me mātou. Ko tō makona tō mātou hihiri! Kia mahi tahi tātou ki te tuhi i tētahi upoko hou kanapa!

He tino manawanui ngā kaimahi ratonga kiritaki me ngā kaihoko, ā, he pai katoa rātou ki te reo Ingarihi, he tere te taenga mai o te hua, he kaiwhakarato pai hoki.

Ngā kāwai hua

-

Waea

-

Ī-mēra

-

Whatsapp

-

WeChat

Hūri

150 0000 2421

-

Runga